Matrix Bottling Group takes drinks from concept to shelf, bringing scalable, clean-label bottling to top beverage brands. We leverage advanced automation and expert formulation to deliver national-level bottling services for our partners.

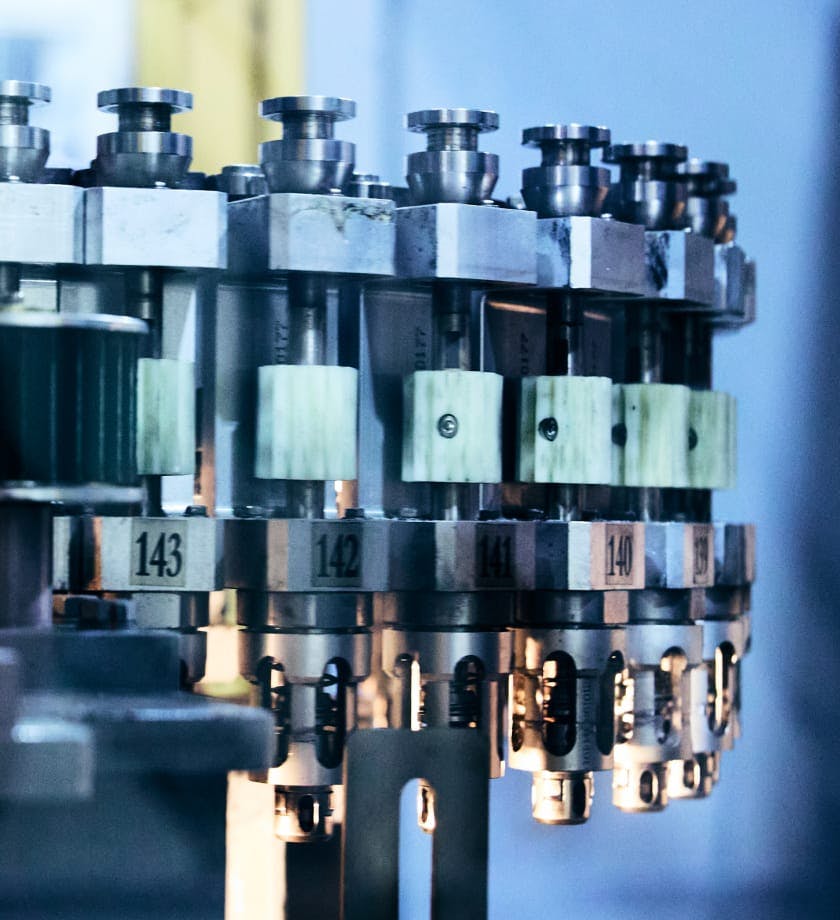

We operate three coast-to-coast facilities in California, Nevada, and North Carolina, and all of our bottling plants utilize automated multi-lane precision. With this technology, we can produce up to 45,000 bottles per hour with minimal downtime.